A 4-storey glulam + CLT structure in British Columbia was built during summer conditions, where moisture ingress posed risks at junctions, penetrations, below-grade transitions, and window openings.

Products

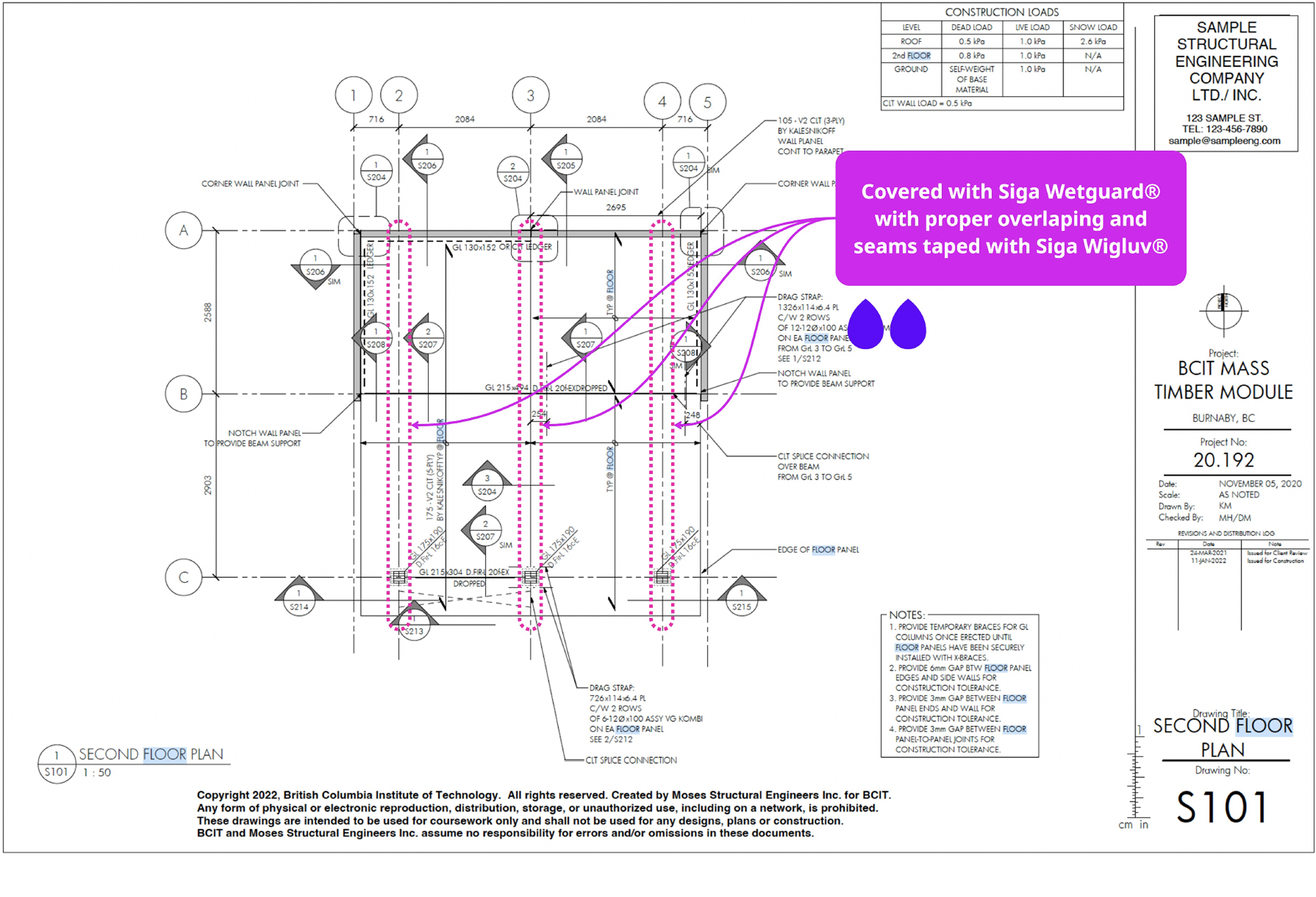

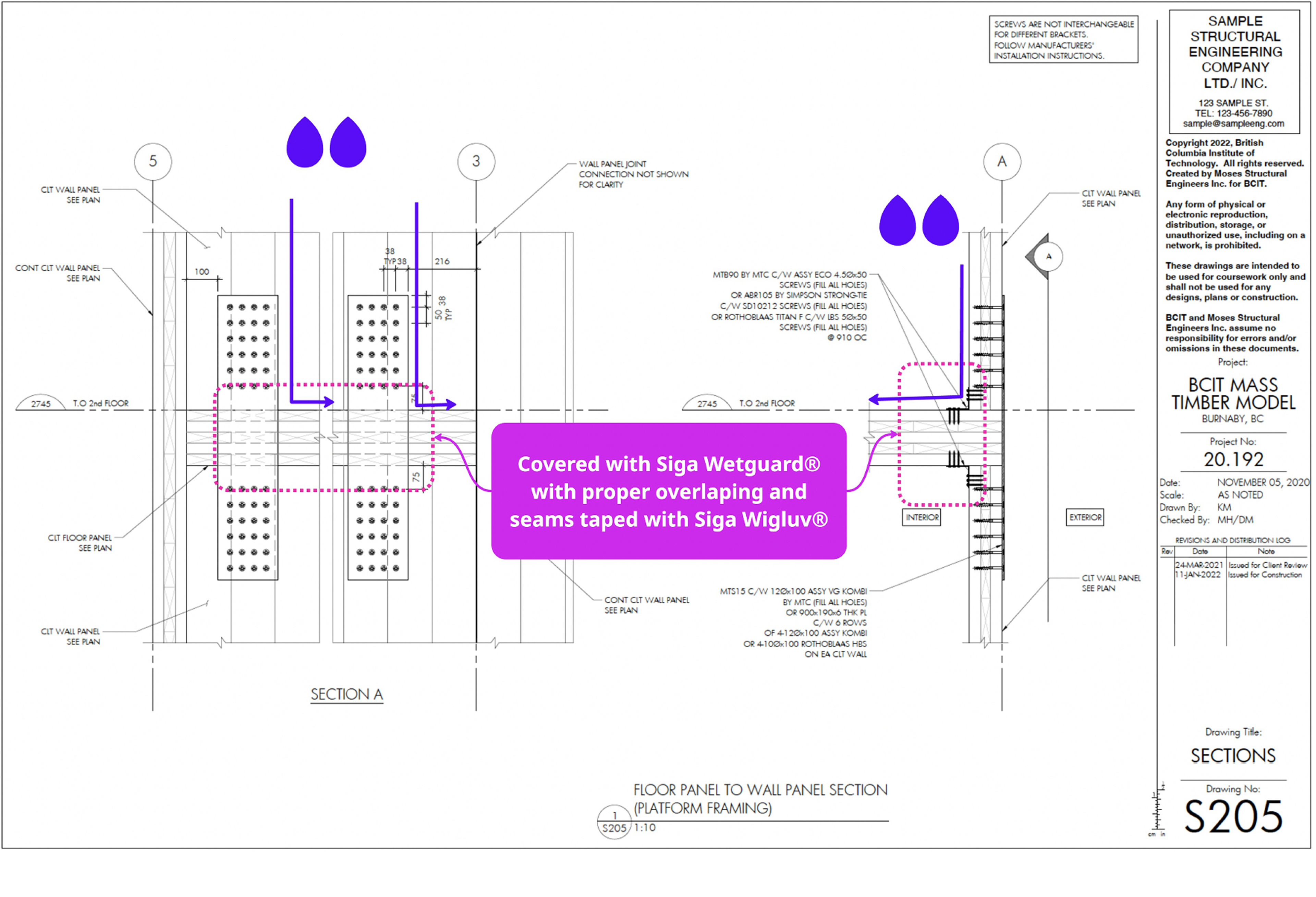

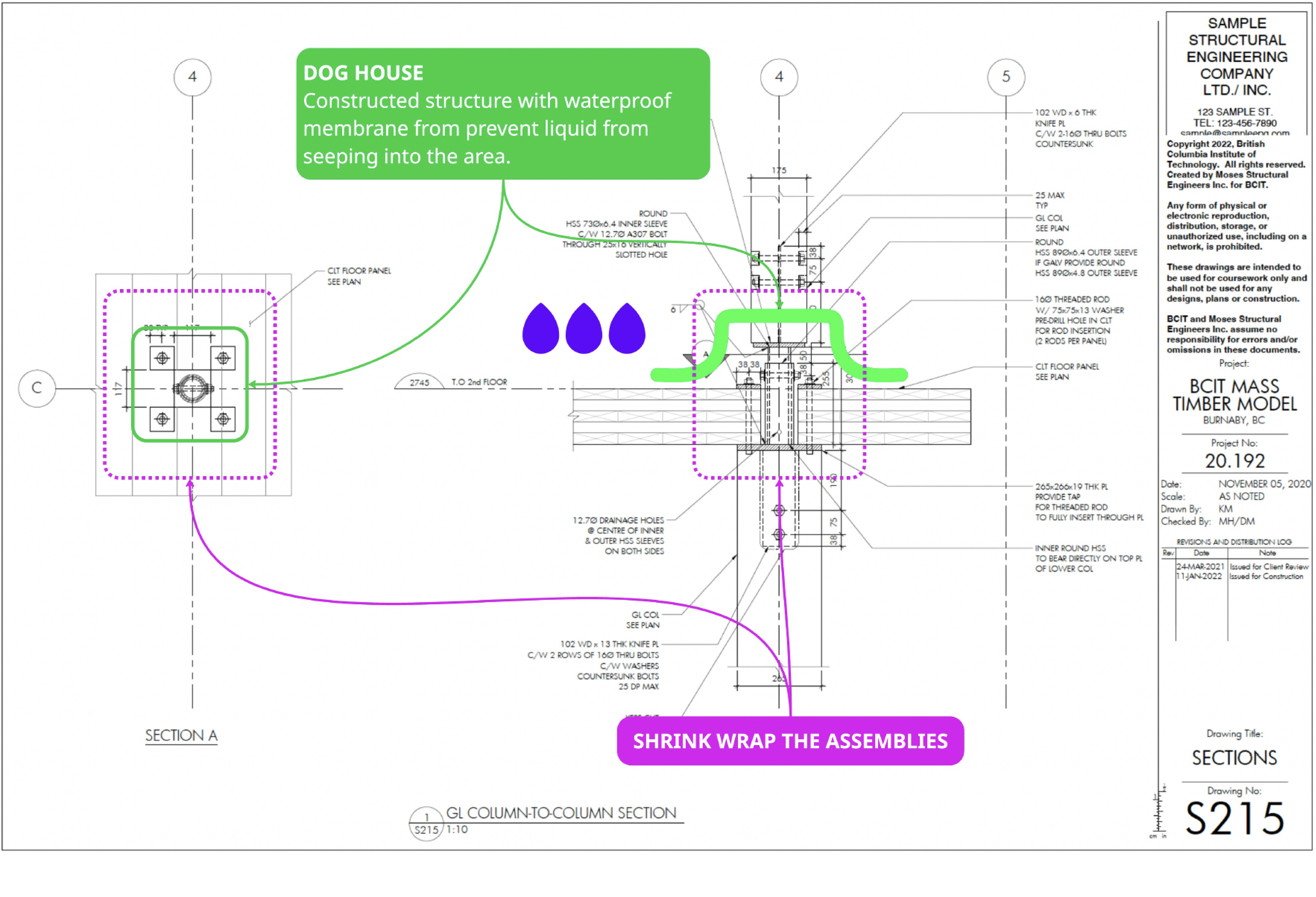

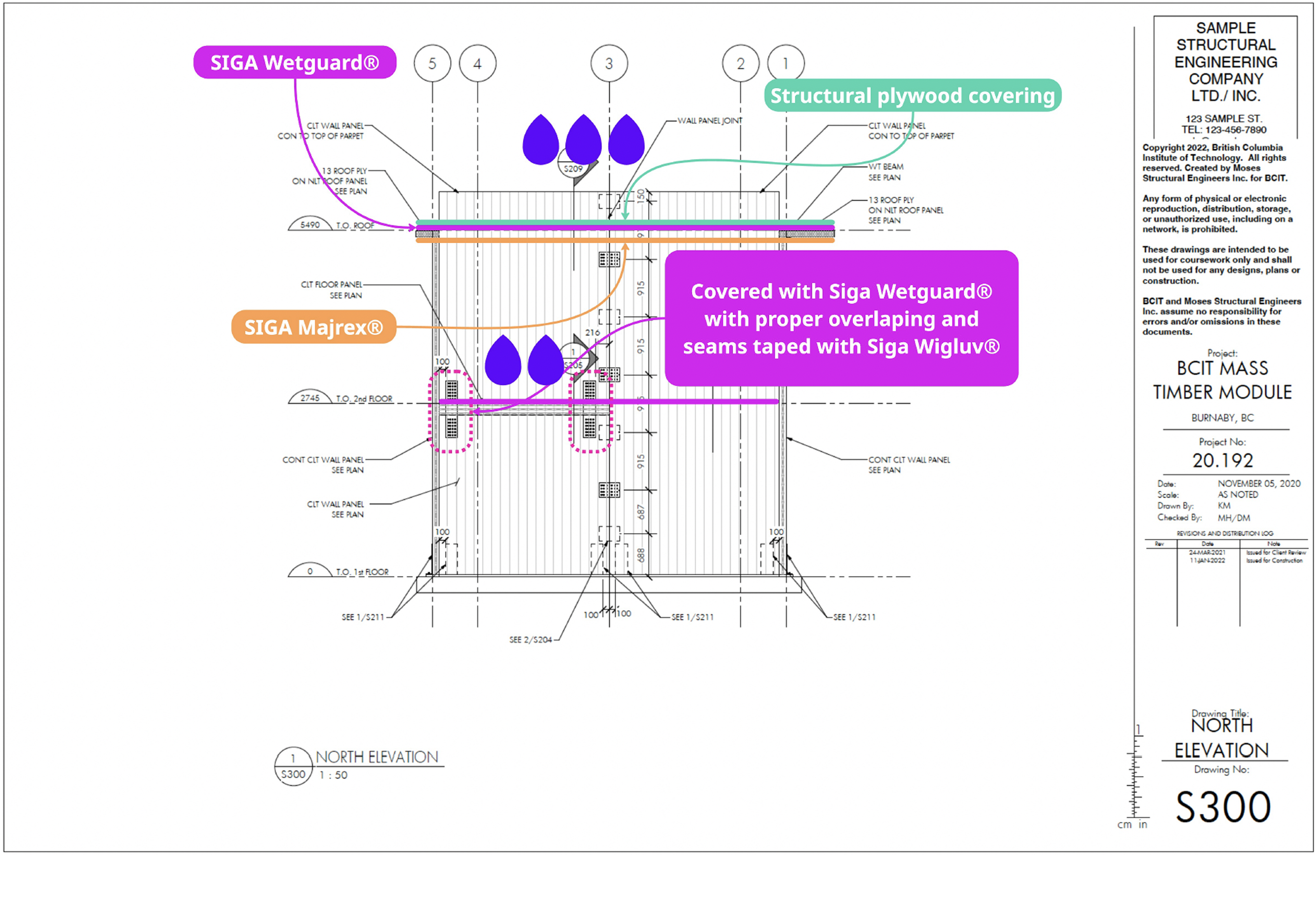

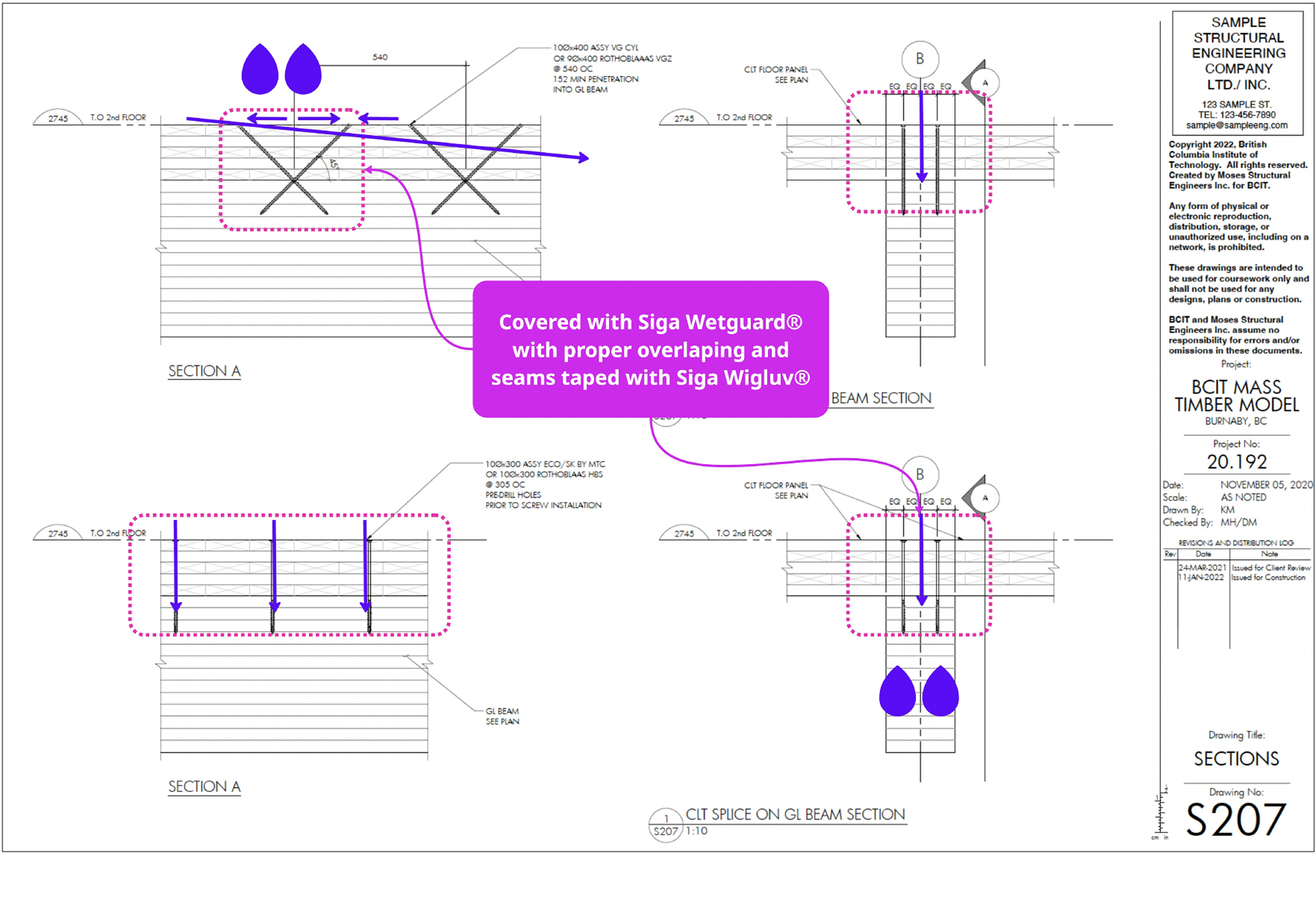

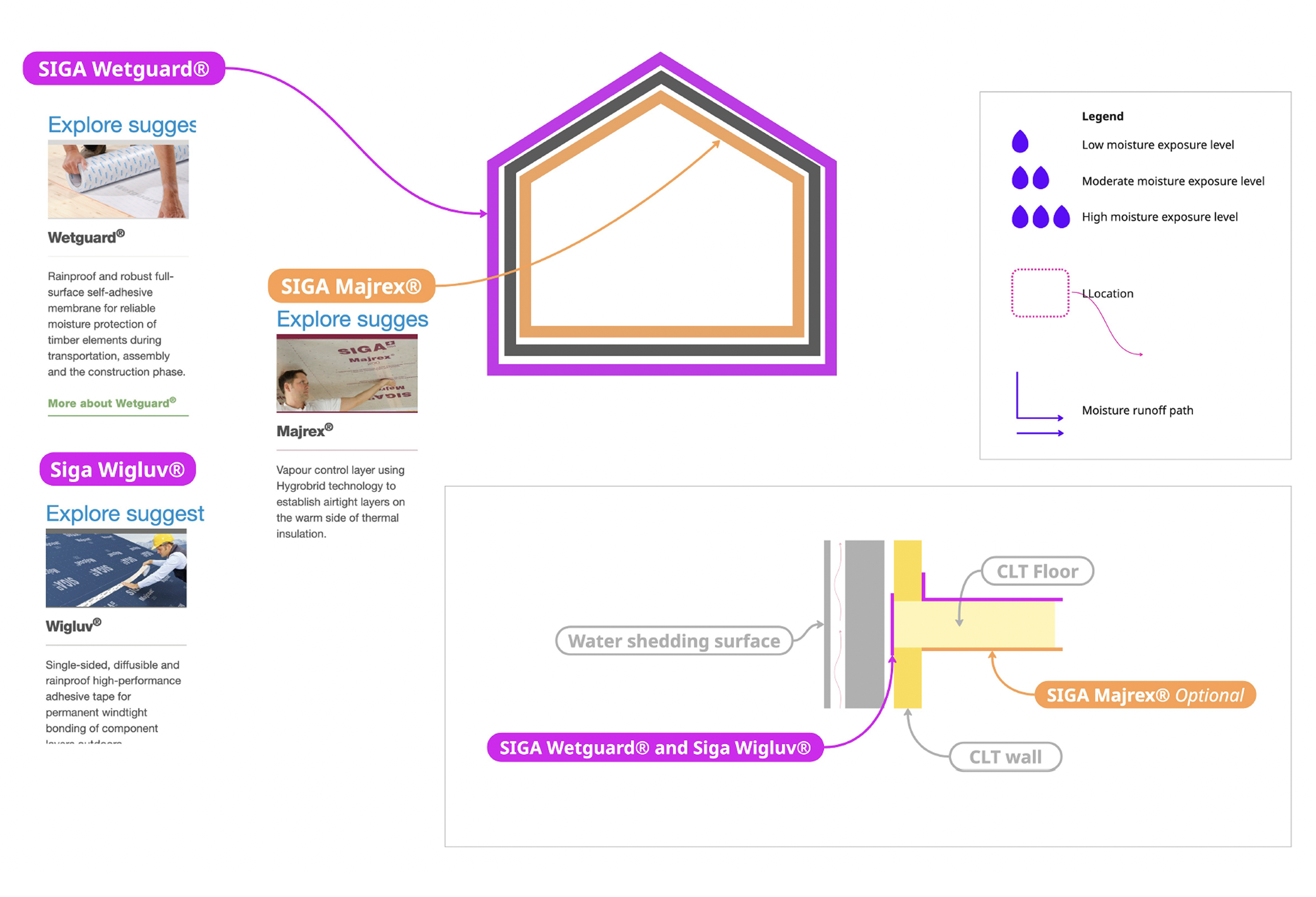

SIGA Wetguard® protected CLT surfaces during transport and erection.

SIGA Wigluv® sealed seams, cut ends, openings, and service penetrations.

SIGA Majrex® provided directional vapour control on select ceiling panels.

Strategy

1. Waterproof membranes were installed early, where the timber met the concrete.

2. Extra strips were added around parapets, windows, and service openings to maintain continuous barriers.

3. Temporary tarps, drainage, and vents protected the structure when it was exposed to rain.

4. Breathable membranes were used to allow any trapped moisture to dry out safely.

Reflection

SIGA membranes balanced vapour permeability with resistance to bulk water—critical for protecting assemblies during construction. Sequencing at parapets, windows, and timber–concrete joints ensured continuous barriers and safeguarded Douglas fir components. Moisture control through transport, installation, and post-construction preservation ensures structural integrity and long-term thermal performance.

References

RDH Building Science (2021). Mass Timber Moisture Management Guide.

Richardson, D. (2025). Building Enclosures for Mass Timber (TMBR 1040). BCIT ZEB Learning Centre.

SIGA (2020). CLT Guide: Membranes, Tapes, and Detailing.

Ontario Building Code (2024 Edition). Part 5: Environmental Separation.

Richardson, D. (2025). Building Enclosures for Mass Timber (TMBR 1040). BCIT ZEB Learning Centre.

SIGA (2020). CLT Guide: Membranes, Tapes, and Detailing.

Ontario Building Code (2024 Edition). Part 5: Environmental Separation.